EI4.0 Data Analytics

EI4.0 is Electroimpact’s data analytics software package. It analyzes logs generated during operation of the AFP machine and presents users with insights distilled from those logs. The up-to-date information provided by EI4.0 is vital for mangers, maintenance staff, part programmers and machine operators, all of whom need to be able to make informed decisions quickly based on real data.

For the Manager

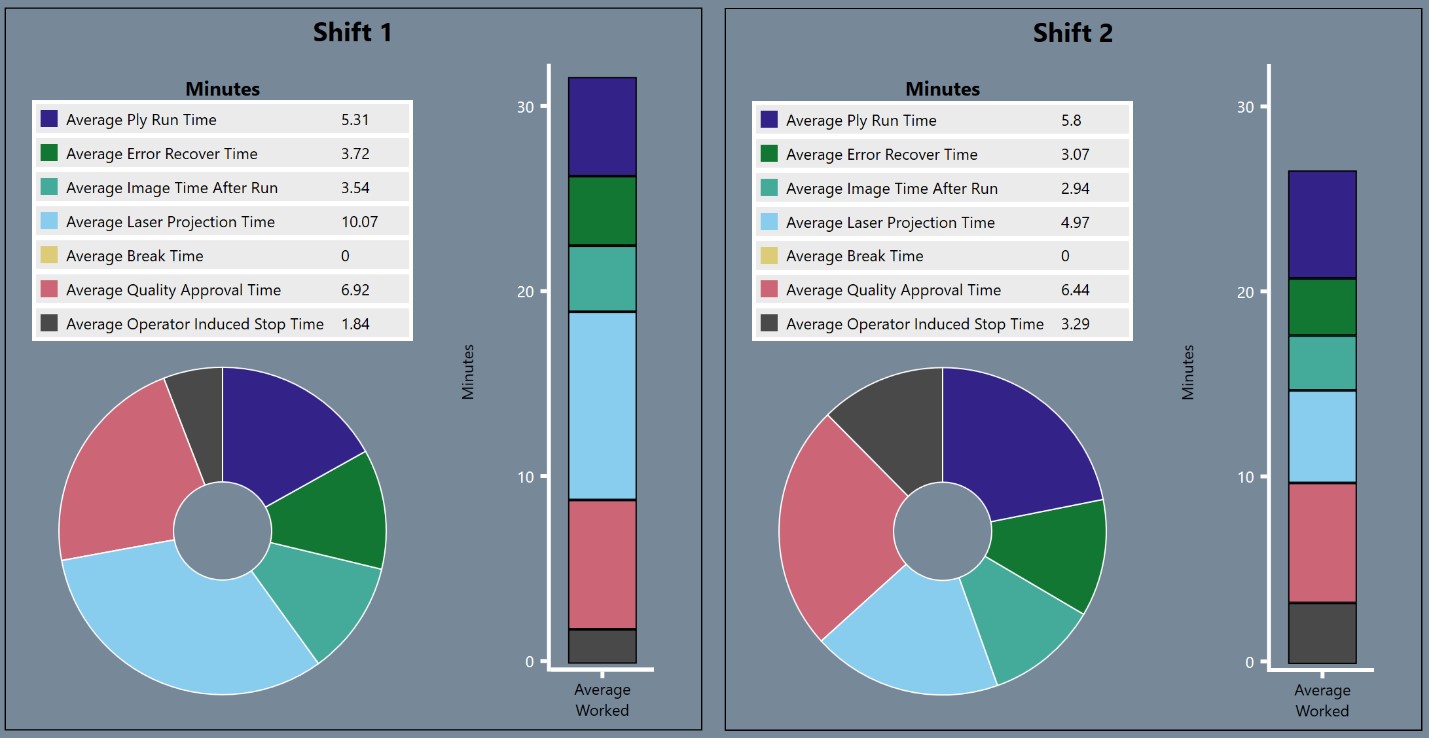

In order to make informed management decisions, it’s necessary to have a real picture of how the cell is being used and where problems are arising. EI4.0 captures all aspects of the production process and allows managers to see how statistics like machine reliability, floor-to-floor rate, and equipment utilization vary over time. Performance can also be compared between shifts.

As an example, in the following pair of pie charts, which represent average time spent on various tasks over a large number of builds, Shift 2 tends to spend about half as much time inspecting the part using the laser projector as Shift 1 does. Perhaps there is knowledge among the workers in Shift 2 that needs to be communicated to Shift 1 to help them work more quickly.

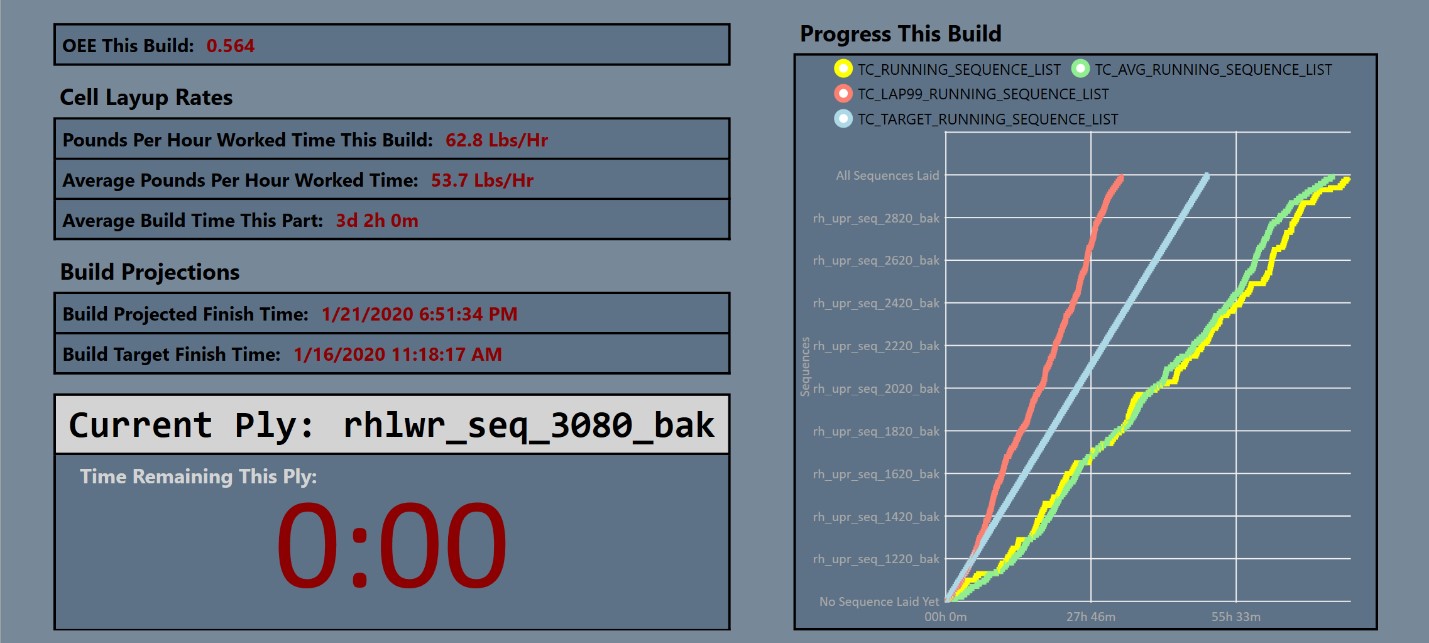

For the Machine Operator

Building an AFP part involves many repetitive sub-processes, as the part needs to be laid up layer by layer. The EI4.0 part build dashboard prevents the machine operation team from getting lost in the weeds by providing production benchmarks based on past performance. The dashboard compares progress through the current build with historical averages and can be programmed to give the operators production targets for each shift.

For the Maintenance Technician

EI4.0 allows the user to drill down through detailed historical information on the performance of individual parts of the AFP machine. This drill-down capability is useful for maintenance workers who are interested in identifying points of failure and fixing them to keep the machine working at capacity.

As an example, if the maintenance technician wants to diagnose head performance, he can graph Mean Strips Between Failure by head over a set period of time, say the last two months.

Head 1 has significantly fewer Mean Strips Between Failure.

To investigate, the technician can drill down further to see frequency of tow error by head lane.

Lane 2 seems to experience significantly more errors than other lanes, and lanes 6 and 9 are almost tied for second place. Maybe it’s time to replace some hardware to bring the tow error rate down.

For the Part Programmer

EI4.0 can identify individual courses which tend to produce a greater number of tow errors. Based on this information, the part programmer can investigate the NC program in order to determine why those certain courses tend to cause layup problems.

Increasing Reliability and Machine Utilization

It is Electroimpact’s goal to help all our customers achieve stellar machine performance and reliability, and to provide customers with data that helps them to keep the machine laying tow as much of the time as is possible. EI4.0 is a keystone in this effort, providing the data necessary for continual process improvement.